The silicone sportEX bracelet by ENERGETIX Bingen became quite a success almost immediately after it was launched. The first delivery sold out within just a few days and the demand for subsequent shipments was extraordinarily high.

Full of innovation and quality: the flexible silicone bracelet with integrated neodymium magnets

The silicone sportEX bracelet that combines a beautiful and modern design with extraordinary practicality comes with strong neodymium magnets that are encapsulated in almost indestructible silicone – not only for a young and sporting audience in brilliant colours but also for all those who want to wear a robust bracelet even in demanding conditions. A bracelet that will survive the shower, sauna, swimming pool and almost any other sports, leisure, household or hobby activity without suffering any damage!

How is the sportEX bracelet made?

ENERGETIX Bingen developed and designed the sportEX bracelet and even closely supervised the test batch and first production runs. ENERGETIX also monitored the implementation of its quality standards at site.

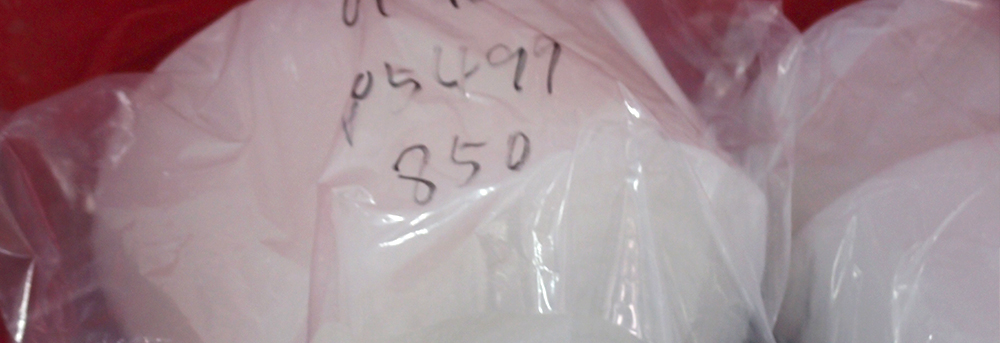

The production of sportEX bracelets commences with a high-quality silicone mass, which is manufactured to satisfy European safety standards. The entire production process is governed by EU regulations (EC), which are based on the REACH system (Registration, Evaluation, Authorisation and Restriction of Chemicals) that specifies the exclusive use of registered materials and the avoidance of hazardous substances in products manufactured in accordance with the EC’s RoHS directive (Restriction of (the use of certain) hazardous substances). These regulations apply to such high-quality products as cars, electrical and electronic appliances and, of course, to sportEX by ENERGETIX Bingen.

The raw silicone is dyed in accordance with ENERGETIX’s specifications – in this case a strong pink – and shaped to the right size.

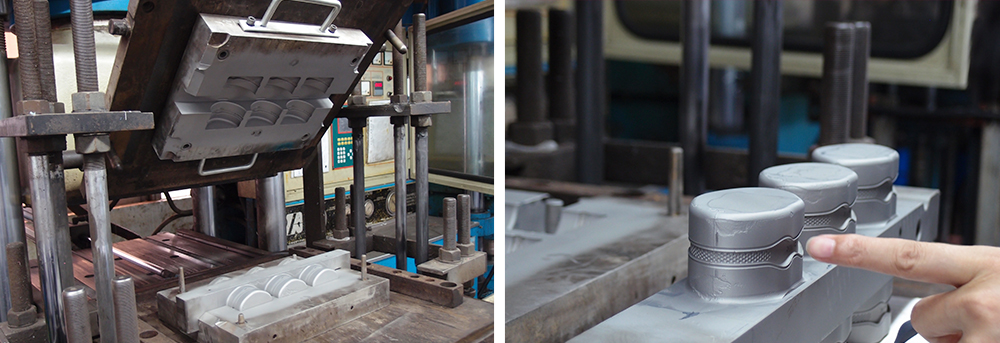

The strips and three magnets per bracelet are then placed very carefully with great accuracy in a large press and pressed at a very high pressure and temperature for a precisely defined period of time – they are „baked“ so to speak! This is where the bracelets take their final shape and where the ENERGETIX lettering in clear writing and Braille as well as all the design elements are applied. This turns the raw silicone into a soft and flexible item of jewellery that is pleasant to wear.

In the next stage of work, the sportEX bracelets are taken out of the press to then be finished.

At this point in production, the sports bracelets still possess the unavoidable residues from the pressing stage on them. This indicates that sufficient material was in the press and that no holes or hollow spaces have spoilt the jewellery.

After the excess silicone has been removed and the bracelets have been cleaned, a special protective film is applied that largely prevents them from attracting dust as is frequently the case with cheap products. The sportEX bracelets are finished by placing them in the stabilization oven for an extended period of time.

The sequence of work described above shows how complex the production of sportEX silicone bracelets actually is. But it is only this elaborate manufacturing process that makes it possible to guarantee that the colour will last and that the bracelets will be sufficiently durable. It makes them stand out from many the mass-produced and frequently only injection-moulded pieces on the market. And it is not without pride that Dr Thiel, COO at ENERGETIX, reported the success of „having been able to work with a renowned producer to technically structure the relatively complex process in such a way that we are able to guarantee a magnetic field strength of 1,200 per magnet to our distributors and customers in spite of the high processing temperature“.

So it only remains to wish everybody lots of fun with the new sports bracelets.